Penna Flame Offers a Wide Array of Services!

Whether You Need It Cold or Hot, We're Here to Help Out!

To ensure proper heat treating of your part, it will typically require some type of additional processing that utilizes high heat or extreme cold.

At Penna Flame, we provide tempering or stress relieving utilizing five ovens that are capable of heating parts to temperatures ranging from 200˚F to 1,250˚F. These ovens, coupled with digital recording technology, ensure that every load has the highest accuracy and traceability.

For other applications, we utilize cryogenics to complete the hardening process. This process is performed in a computer controlled chamber that slowly lowers the temperature for an appropriate period of time before returning it to ambient temperature. This "super cold" treatment guarantees the part's dimensional stability for more precise finish tolerances and improved surface wear resistance.

Stress Relieving

Proper stress relieving of various parts and fabrications is essential in many heat treating processes. That is why Penna Flame is equipped to handle your stress relieving needs! You can trust us to process your parts in five workings days or less. Our ovens are equipped to digitally record both oven and part temperatures to ensure load accuracy and traceability. We are able to generate a process chart at your request, and can accommodate the following:

Capabilities:

- Temperature Range: 200˚F - 1,250˚F

- Temperature Uniformity: +/- 15° F

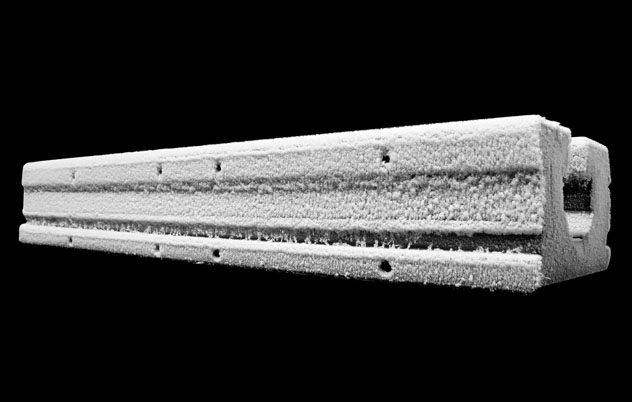

- Maximum Size: 16' Long x 10' Wide x 8' High (We are able to extend the length to 19'8" if the height is below 3')

- Maximum Weight: 40,000 lbs

Tempering / Baking

All of the parts we treat receive a final tempering procedure that completes the heat treating process and ensures high accuracy and repeatability. With low temperature baking of chrome plating, we're able to remove hydrogen embrittlement and improve the integrity of the part. The capabilities of the ovens will max out the same as stress relieving. These ovens are equipped with digital recording devices that record both oven and part temperatures to ensure load accuracy and traceability. Plus, we can generate a process chart at your request.

Capabilities:

- Temperature Range: 200˚F - 850˚F

- Maximum Size: 16' Long x 10' Wide x 8' High (We are able to extend the length to 19'8" if the height is below 3')

- Maximum Weight: 40,000 lbs

Cryogenics

Cryogenics employs cold or ultra-low temperatures to complete the hardening transformation of Retained Austenite to Martensite in some materials and to stabilize others. While "Shallow Cryogenics" is limited to the -120°F range, "Deep Cryogenics" refers to the significantly greater results of temperatures as low as -300°F. At PFI, you can choose from the full range of 0 to -300°F, with the confidence of computer controls to ensure consistency and to reduce thermal shock effect.

Capabilities:

- Temperature Range: 0˚F to -300˚ F

- Maximum Size: 14' Long x 3'11" Wide x 4' High

- Maximum Weight: 10,000 lbs