"Welcome to Penna Flame..."

"Our team is excited to help you

with your heat treating project!"

Serving the steel, mining, railroad, machine-tool, automotive, and other varied industries, Penna Flame Industries has been meeting your diverse surface hardening needs since 1968.

You will experience ideal communication that is responsive to your needs. You can expect the highest level of quality and repeatability when you trust us with your products. We are always aiming to exceed your expectations!

Our average turnaround is 4-6 business days but this could vary depending upon the process required. For more specific turnaround times, based on the process required, please refer to each individual page: Flame Hardening, Robotic Hardening, Added Manufacturing, Furnaces/Cryogenics, or contact a member of our customer service team.

Contact us and let us know how we can meet the specific requirements of your job. Our sales team is ready to discuss your surface hardening requirements today.

Meet Our Sales and Customer Service Team...

Click below to find out how they will work with you to complete your heat treating project on time and to your desired specifications!

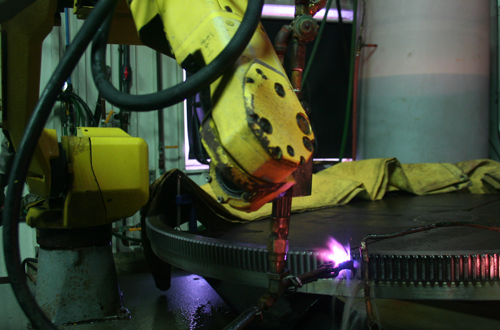

New robotic induction machine hardening a part to our

customer's specific requirements.

State-of-the-Art Robotics

Offers Precision, Reliability,

And Quick Turnaround!

"Introducing robots allowed us to handle projects of various sizes and quantities quicker and more cost-effectively than ever before!"

- James P. Orr, President

Penna Flame leads the industry in using advanced robotics capabilities to precisely and consistently flame harden or induction harden steel parts to your specifications This process improves wear resistance and increases the longevity of the part. Plus, by using robotic flame hardening and our newest advanced robotic induction hardening, we can turn around your high-quantity project faster than ever before, while maintaining consistency throughout the run and saving you money on your bottom line in the process!

Here's How We Can Meet Your Surface Hardening Needs

Flame Hardening

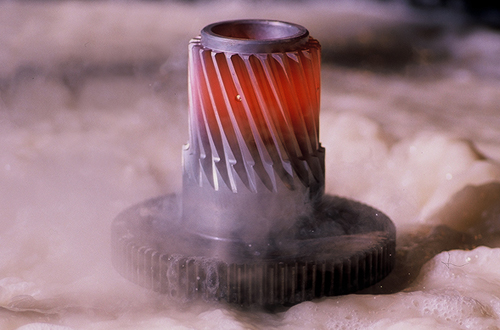

We offer progressive, spin, and progressive spin flame hardening, which provide quick, economical and selective hardening of your parts to ensure increased wear resistance and longer life. We have the latest temperature measuring equipment and five large ovens that are capable of heating / stress relieving parts up to 1,250ºF. These ovens, coupled with digital recording technology, ensure complete accuracy and traceability.

Robotic Flame Hardening

Our computerized robotic surface hardening systems have revolutionized the surface hardening industry! Our advanced robots, coupled with programmable index tables, provide an automation system that helps decrease production time while maintaining the highest quality in precision surface hardening. Typical applications include rings, complex gears, bearing assembiles and high volume production orders.

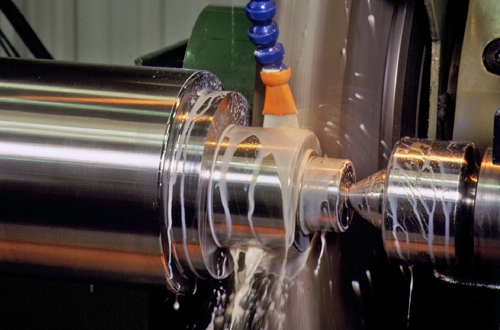

Robotic Induction Hardening

Penna Flame brings you a new generation of robotic induction surface hardening applications that utilizes the principle of electromagnetic induction to heat the surface layer of a part and harden it to your specific requirements. This new process enables us to handle larger volume runs faster and more cost-effectively than ever before and you get the same precision and reliabilty as with our other flame hardening processes!

Added Manufacturing

Our computerized robotic surface hardening systems have revolutionized the surface hardening industry! Our advanced robots, coupled with programmable index tables, provide an automation system that helps decrease production time while maintaining the highest quality in precision surface hardening. Typical applications include rings, complex gears, bearing assembiles and high volume production orders.